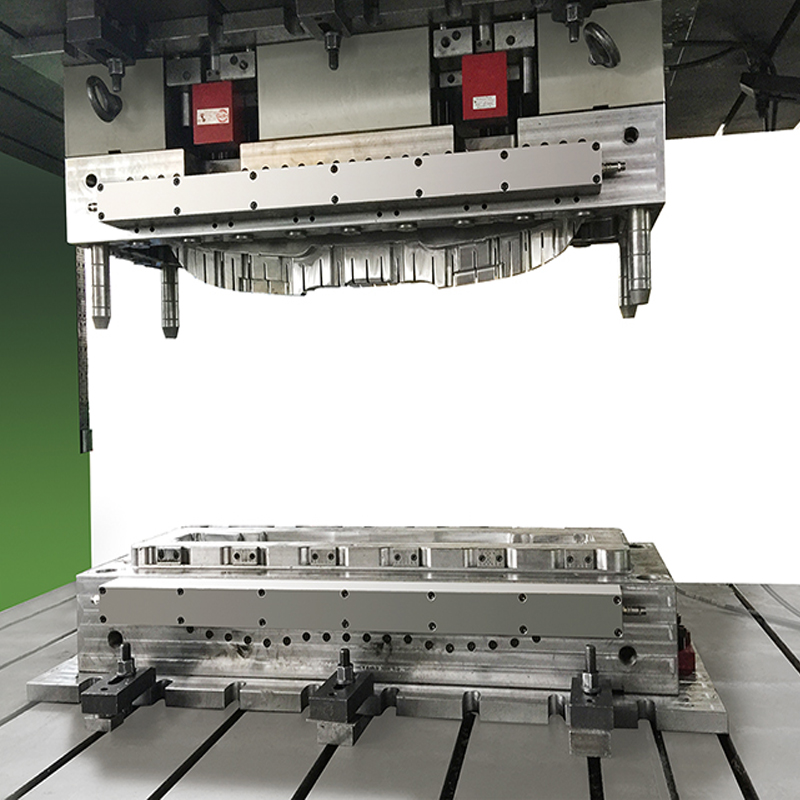

LFT Mold Export To Iran

We have successful experience in making various kinds of moulds for:Auto Parts: Bumper, engine hood, chassis, front panel, truck door, dashboard, lampshade, foot board, fender etc.Communication and Electric appliances: Electric meter box, cable branch box, transforming and distributing box, air-cond......

Send Inquiry

Product Description

We have successful experience in making various kinds of moulds for:

Auto Parts: Bumper, engine hood, chassis, front panel, truck door, dashboard, lampshade, foot board, fender etc.

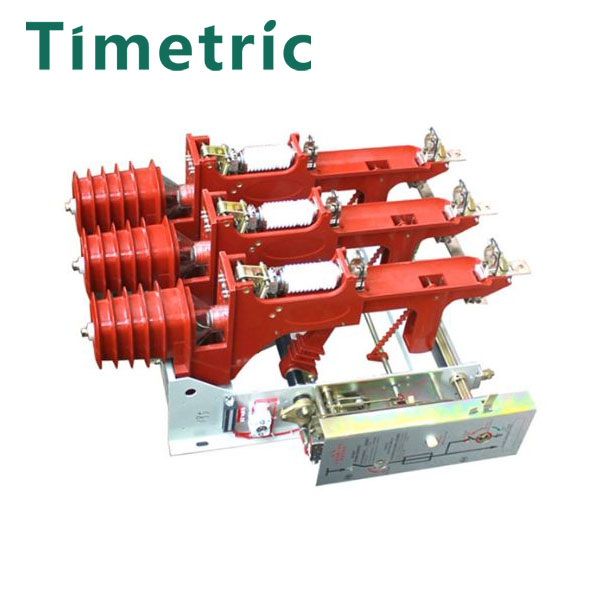

Communication and Electric appliances: Electric meter box, cable branch box, transforming and distributing box, air-condition, satellite dish etc.

Sanitary and Kitchenware: Bathtub, wash basin, sink, ceiling board, chassis, wallboard wainscot etc.

Door: We have unique experience in making SMC/MDF/HDF doorskin mould with wood grain.

Transportation: SMC Motor boat, SMC railway frame, train seat, roof, window frame and lavatory etc.

Construction: Water tank, septic-tank etc.

The customers of Huacheng Mould are all over the world, such as America, Italy, Malaysia, Thailand, Iran and so on. Our products enjoy the highest quality with the most reasonable price.

LFT is bulk molding material that feature continuous fiber filaments running the full length of the pellet allowing these materials to exhibit simultaneous improvements in strength, stiffness, and impact resistance over a wide temperature range.

Meanwhile, D-LFT (Direct-long fiber thermoplastics) is available for injection or compression molding. Most D-LFT systems, feed glass roving into a twin-screw extruder (TSE), where it is chopped by the screws as it is mixed with molten polymer and additives that have been metered in separately. To improve surface finish, some systems use knives to prechop the roving prior to entrance into the TSE. This method generally yields a shorter fiber, while the direct roving feed produces long fibers and yields parts with higher structural performance.

The advantage of D-LFT mold is that it can reduce production cost by elimination of semi-finished products and logistical effort, and increase production flexibility.